7 axis cnc machine A 7 axis CNC machine is a computer-controlled machine tool that uses seven axes of motion to operate. This type of machine is capable of performing complex, multi-dimensional cuts and shapes with high precision . With the right wholesale spare parts sourced, you can maintain optimal performance and reliability for your CNC machines. By ensuring your machinery runs at peak efficiency, you will ultimately optimize the entire manufacturing process and reinforce the success of your business.

0 · y axis cnc lathe

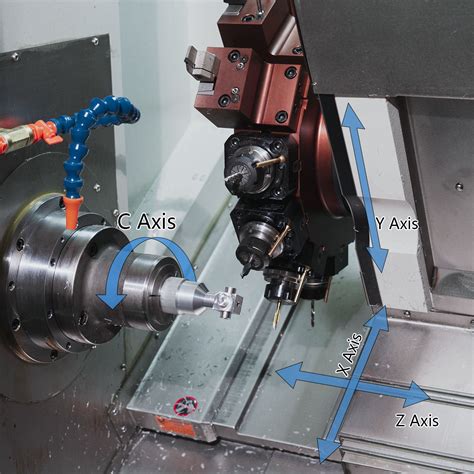

1 · lathe axis explained

2 · cnc xyz axis

3 · cnc machine axis locations diagram

4 · axis identification in cnc machine

5 · 7 axis robot arm cnc

6 · 7 axis machining center

7 · 7 axis cnc machine price

With professional and productive factory, HENGCHANG is one of the leading China mattress machine manufacturers and suppliers. If you are looking for mattress machine, quilt patterns, quilting patterns, bobbin winding machinery made in China or wholesale, or if you want to buy cheap products, please feel free to contact us.

In a nutshell, 7-axis CNC machining combines linear and rotational movements to offer unmatched flexibility and precision. Whether you’re crafting aerospace components or medical .7-Axis CNC Machining 7-axis CNC milling machines can create long, slender, and heavily detailed parts. The 7-axes involved are the usual right-left, top-down, and back-front, followed . A 7 axis CNC machine is a computer-controlled machine tool that uses seven axes of motion to operate. This type of machine is capable of performing complex, multi-dimensional cuts and shapes with high precision . What is 7-axis CNC Machining? 7-axis CNC machining follows the same principle as 5-axis CNC machining with the addition of two more axes, .

y axis cnc lathe

lathe axis explained

Nexturn SA (B) Swiss CNC lathe series represent a cost efficient and productive 7-axis machine for complex precision parts. Three models feature synchronous guide bushings, 7 machining .Expand Machinery presents GENTURN 36-CS 7-axis CNC Swiss machine lathe without guide bushing featuring 27 tools and more. Find out why automating your machine shop with a 7-axis cobot like the OB7 from Productive Robotics is superior to a 6-axis cobot.

Due to the multitasking capabilities, complete automation can be achieved with a 7-axis CNC machine. And manufacturers can design and program the parts with any CAD, CAM software, and generate g-codes to feed into the CNC machine.

In a nutshell, 7-axis CNC machining combines linear and rotational movements to offer unmatched flexibility and precision. Whether you’re crafting aerospace components or medical implants, this technology can revolutionize your manufacturing process.7-Axis CNC Machining 7-axis CNC milling machines can create long, slender, and heavily detailed parts. The 7-axes involved are the usual right-left, top-down, and back-front, followed by the axes defined by the spinning of the tool, rotation of the part, rotation of the tool head, and movement for clamping, reclamping, or removing the part. A 7 axis CNC machine is a computer-controlled machine tool that uses seven axes of motion to operate. This type of machine is capable of performing complex, multi-dimensional cuts and shapes with high precision and accuracy.

steel wall cabinet mirror

cnc xyz axis

steel wool 0000 on kitchen cabinets

What is 7-axis CNC Machining? 7-axis CNC machining follows the same principle as 5-axis CNC machining with the addition of two more axes, making it a more versatile CNC machining technology. It usually includes: X axis for vertical rotation; Y axis for horizontal rotation; Z axis for depth of the part; A axis for X axis revolutionNexturn SA (B) Swiss CNC lathe series represent a cost efficient and productive 7-axis machine for complex precision parts. Three models feature synchronous guide bushings, 7 machining axes and as many as 22 tools to handle maximum bar diameters of 12mm, 20mm and 32mm.Expand Machinery presents GENTURN 36-CS 7-axis CNC Swiss machine lathe without guide bushing featuring 27 tools and more. Find out why automating your machine shop with a 7-axis cobot like the OB7 from Productive Robotics is superior to a 6-axis cobot.

What Is 7-Axis CNC Machining? 7 axis machining is a complete setup on its own and can manufacture complex parts without having to transfer them to another machine. When the part drops off, it is most often complete. The 7-axis include: X-axis (vertical rotation) Y-axis (horizontal rotation) Z-axis (moving the arm up/down) A-axis (rotating at X .

The ½” bar capacity, 7-axis Citizen L12VII is the perfect machine for your small diameter machining needs. With 15,000 RPM main spindle speeds, this dynamo has a true need for speed! The L12VII allows for a maximum of 28 mounted tools, with 4 live spindles included as standard.Due to the multitasking capabilities, complete automation can be achieved with a 7-axis CNC machine. And manufacturers can design and program the parts with any CAD, CAM software, and generate g-codes to feed into the CNC machine.In a nutshell, 7-axis CNC machining combines linear and rotational movements to offer unmatched flexibility and precision. Whether you’re crafting aerospace components or medical implants, this technology can revolutionize your manufacturing process.

7-Axis CNC Machining 7-axis CNC milling machines can create long, slender, and heavily detailed parts. The 7-axes involved are the usual right-left, top-down, and back-front, followed by the axes defined by the spinning of the tool, rotation of the part, rotation of the tool head, and movement for clamping, reclamping, or removing the part. A 7 axis CNC machine is a computer-controlled machine tool that uses seven axes of motion to operate. This type of machine is capable of performing complex, multi-dimensional cuts and shapes with high precision and accuracy. What is 7-axis CNC Machining? 7-axis CNC machining follows the same principle as 5-axis CNC machining with the addition of two more axes, making it a more versatile CNC machining technology. It usually includes: X axis for vertical rotation; Y axis for horizontal rotation; Z axis for depth of the part; A axis for X axis revolution

cnc machine axis locations diagram

Nexturn SA (B) Swiss CNC lathe series represent a cost efficient and productive 7-axis machine for complex precision parts. Three models feature synchronous guide bushings, 7 machining axes and as many as 22 tools to handle maximum bar diameters of 12mm, 20mm and 32mm.

Expand Machinery presents GENTURN 36-CS 7-axis CNC Swiss machine lathe without guide bushing featuring 27 tools and more.

Find out why automating your machine shop with a 7-axis cobot like the OB7 from Productive Robotics is superior to a 6-axis cobot.

What Is 7-Axis CNC Machining? 7 axis machining is a complete setup on its own and can manufacture complex parts without having to transfer them to another machine. When the part drops off, it is most often complete. The 7-axis include: X-axis (vertical rotation) Y-axis (horizontal rotation) Z-axis (moving the arm up/down) A-axis (rotating at X .

steel vehicle tool box

Struggling to source CNC parts? Explore THECNCSOURCE.COM for easy access to top brands like Renishaw, Blum, Heidenhain, Acu-Rite, Zebra Skimmers and more.

7 axis cnc machine|axis identification in cnc machine